Views: 0 Author: Site Editor Publish Time: 2025-06-11 Origin: Site

Have you ever wondered how to shrink rubber O-rings for a perfect fit? Whether you're working on a DIY project or need to adjust an O-ring for an industrial application, understanding the best methods for shrinking rubber O-rings is essential. In this article, we will discuss how to properly shrink rubber O-rings, the tools required, and best practices for achieving the ideal seal.

Expect to learn about the various techniques used to shrink rubber O-rings, why these methods work, and common mistakes to avoid. By the end, you will be equipped with the knowledge to shrink your rubber O-rings effectively.

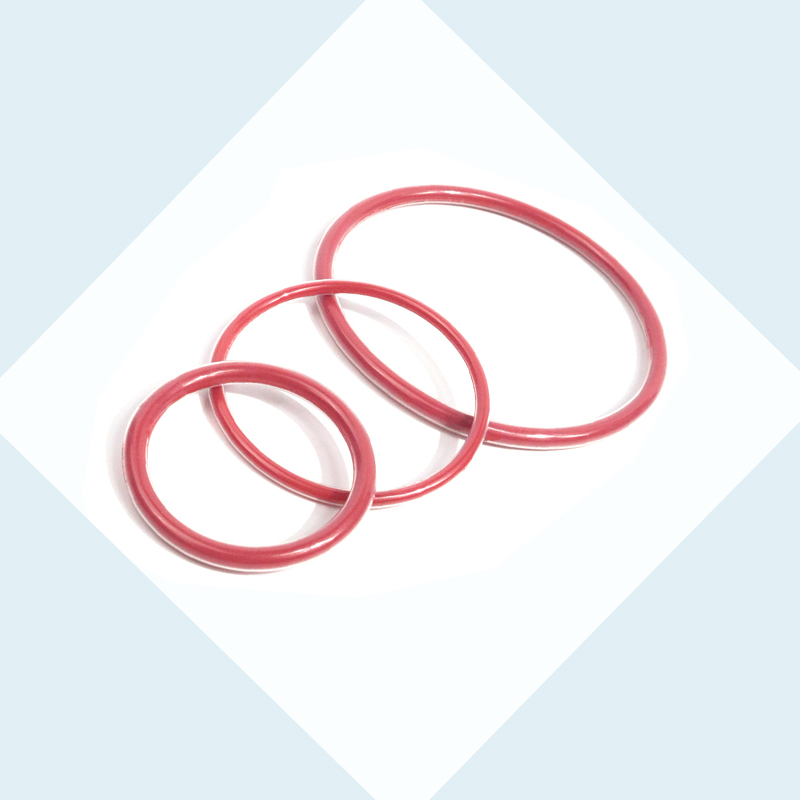

Before diving into the shrinking process, let's first understand what O-rings are. Rubber O-rings are circular seals typically made from elastomers like silicone, nitrile, or fluorocarbon. They are used to prevent the leakage of liquids or gases between two mating surfaces in various mechanical applications. These rings are highly versatile and can be found in industries ranging from automotive to aerospace.

The process of shrinking O-rings may be necessary for several reasons, including:

Adjusting size: When the O-ring is slightly too large for its intended groove or fitting, shrinking it can make it fit snugly, providing a better seal.

Fitting into smaller components: In certain applications, you might need to reduce the O-ring's size to fit into smaller or differently shaped grooves.

Maintenance: Over time, O-rings may expand or lose their form due to usage or environmental conditions. Shrinking them can help restore their original size and elasticity.

There are several methods available for shrinking rubber O-rings, each depending on the material type and size of the ring. Let's explore the most common methods:

Heating is the most common and effective method for shrinking rubber O-rings. Here’s how to do it:

Prepare hot water: Heat water to at least 80°C (176°F). It is important to ensure that the water is not boiling.

Submerge the O-ring: Place the rubber O-ring into the hot water for several minutes. Keep an eye on it to ensure it doesn't get too hot.

Remove and cool: Once the O-ring has shrunk to the desired size, remove it from the water and allow it to cool before using it.

This method works well for most rubber types and can shrink O-rings by a few millimeters.

For more controlled shrinking, you can use an oven to apply heat more evenly to the O-ring.

Set the temperature: Preheat your oven to around 90°C (194°F).

Place the O-ring on a baking sheet: Lay the rubber O-ring on a baking sheet or oven-safe surface.

Bake for a few minutes: Allow the O-ring to bake for about 10-15 minutes. Monitor the O-ring closely to ensure it does not overheat.

Cool down: Remove the O-ring from the oven and let it cool naturally before using it.

This method can be particularly useful for larger O-rings and those made of synthetic rubbers.

While not as common as the heating methods, some chemicals can be used to shrink rubber O-rings. This process involves applying a chemical solution that causes the rubber to contract.

Apply the chemical solution: Use a specialized chemical solution designed for rubber shrinkage.

Allow the solution to react: Let the solution work for several hours, or as directed by the manufacturer.

Rinse and dry: After the O-ring has shrunk, rinse it thoroughly with water to remove any chemical residues, and allow it to dry completely.

This method is best for very specific applications and is less commonly used than heat-based techniques.

While shrinking rubber O-rings can be a quick solution, there are a few things you should keep in mind before proceeding:

Material type: Different rubber materials react differently to heat. Silicone, for example, shrinks well when heated, but other materials might degrade if overheated.

Groove tolerance: Make sure that after shrinking, the O-ring still fits into its groove properly. Too much shrinkage could cause it to become too tight and affect the seal's performance.

Elasticity: Excessive heating or chemical shrinking can reduce the O-ring's elasticity, which is essential for maintaining an effective seal over time.

Overheating: Applying too much heat can cause the rubber to degrade, leading to cracks or loss of flexibility.

Not cooling properly: If the O-ring is not allowed to cool and set properly, it could lose its intended form or shrink unevenly.

Using incorrect chemicals: Not all chemicals are suitable for shrinking rubber. Always use solutions designed for this purpose.

Shrinking rubber O-rings can be an essential technique for maintaining the integrity of seals in mechanical applications. Whether you're adjusting the size of an O-ring for a more secure fit or restoring its form for better performance, knowing how to shrink O-rings effectively is a valuable skill. By following the methods outlined in this article, you can ensure that your rubber O-rings perform optimally and provide the necessary seal in your projects.

For your O-ring needs, whether for maintenance or production, consider purchasing from Ningbo Leyipu Electronic Technology Co., Ltd., a trusted leader in providing high-quality sealing products.

A: Measure the O-ring's inner diameter, outer diameter, and thickness to ensure it fits correctly in the groove or fitting.

A: Most rubber O-rings, especially silicone, can be shrunk using heat, but it's important to check the material's tolerance before applying heat.

A: Regular maintenance and keeping the O-rings away from excessive heat and chemicals can help preserve their shape and functionality.

content is empty!

content is empty!